AUTOMATED WORKSHOPS :

MOBILE ROBOTICS :

MOBILE ROBOTICS :

A mobile robot is a mechanical, electronic and computerized system physically influencing its environment in order to reach a goal assigned to it. It is equipped with functions of perception, decision and action. It will thus be able to perform diverse tasks, in various manners, and accurately accomplish its purpose, even when encountering new and unexpected situations.

SUPPLY OF ROBOTIC UNITS BY MOBILE ROBOT :

SUPPLY OF ROBOTIC UNITS BY MOBILE ROBOT :

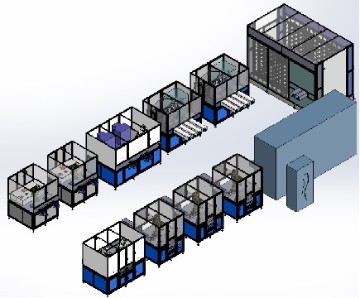

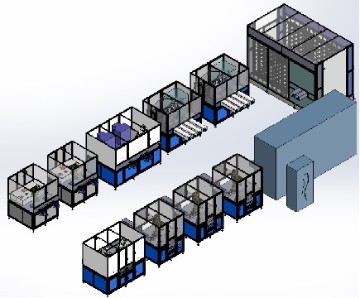

In association with ROBOSOFT, ALPROBOTIC has adapted a mobile robot devoted to the automatic supply of its sandblasting, laser marking, control units...

This mobile robot is equipped with a conveyor that brings trays of parts. It unloads and loads the production robotic units and transfers the trays from one unit to another.

It is connected to an automated TRISTOCK (number of locations to be defined according to needs) and managed by a monitoring software designed by ALPROBOTIC.

Cycle time : Approximately 2 to 3mn per transfer.

Autonomy : 8hrs (or 2 mobile robots per workshop).

AUTOMATED CLEANING LINE :

ULTRASONIC CLEANING :

ULTRASONIC CLEANING :

FISA offers a complete range of magnetostrictive, piezo-electric and multi-frequency ultra-sounds to satisfy all cleaning requirements.

The mechanical effect of ultrasonic cleaning can vary depending on various factors such as: the shape and weight of the parts, the temperature and the concentration of the bath, the types of detergents and contaminants.

DE-GREASING LINE INTEGRATION :

DE-GREASING LINE INTEGRATION :

ALPROBOTIC designs and installs workshops dedicated to the production of small parts with high added value (surgical implants, watchmaking parts, aeronautics...).

In association with FISA, ALPROBOTIC integrates automatically-managed cleaning lines to its workshops. The parts are cleaned in trays. The trays are brought by robots from a TriSTOCK, then are conveyed on output to robotic production units (sandblasting, anodization, quality control, laser marking...).

Cycle time : from 6mn per tray.

Autonomy : continuous operating with mobile robots.

AUTOMATED SANDBLASTING :

SANDBLASTING :

SANDBLASTING :

Sandblasting consists of propelling angular grains (sand) on a surface in order to give it a roughness corresponding to the granulometry of the abrasive used.

Shotpeening consists of propelling micro-beads on a surface in order to etch it slightly without causing damage. Shot peening is used for the cleaning and etching of mechanical parts or to achieve an esthetic finish.

AUTOMATED UNITS :

AUTOMATED UNITS :

In association with ARENA, ALPROBOTIC has developped an innovative and patented sandblasting process - shot peening of high added value parts. The parts are identified by camera or referenced on a tray. The robot moves the part in front of the nozzle in order to process all surfaces while guaranteeing impact speed, sandblasting distance and aligned coverage. The cyclonic system ensures the constant quality of the abrasive and reduces its consumption. The flow of projection is controlled.

Cycle time : from 20 s per part.

Autonomy : between 4 and 16hrs operating on a 3x8hr basis.

AUTOMATED ANODIZATION :

ANODIZATION :

ANODIZATION :

SELENIUM MEDICAL carries out specific treatments of anodic oxidizing and passivation on the two main titanium alloys (T40 and TA6V ELI) and offers the treatment of a large range of stainless steels, using processes developed for the protection and improvement of medical devices.

AUTOMATED UNITS :

In association with SELENIUM MEDICAL, ALPROBOTIC has developed anodization units dedicated to small parts of high added value (surgical implants among others).

From bulk or tray dispensing, the robot moves the parts between different acid, rising and drying baths. This particular handling of the parts is carried out in baskets or by single unit.

Cycle time : between 5 to 6s per part in place.

Autonomy : between 4 and 16hrs operating on a 3x8hr basis.

DIMENSIONNAL CONTROL :

DIMENSIONAL CONTROL :

DIMENSIONAL CONTROL :

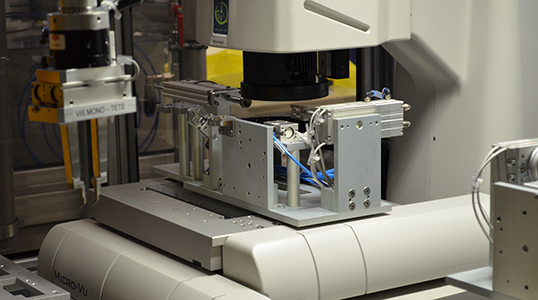

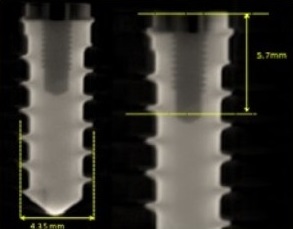

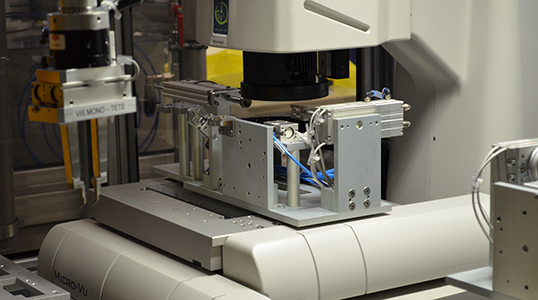

Marketed by MCE, VERTEX is a contactless tri-dimensional measuring machine that carries out automatic controls with micron accuracy.

VERTEX™ can control all dimensional measurements of a part, as well as its surface finish and its roughness using its embedded multi-sensor technology.

AUTOMATED UNITS :

AUTOMATED UNITS :

In association with MCE, ALPROBOTIC has developed dimensional control units dedicated to small high value added parts (surgical implants, watchmaking parts, aeronautics...).

From bulk or tray dispensing, the robot places the parts on suitable supports and launches the measuring programs through the Ethernet network. The report is transmitted to the robot that puts the NOK parts aside. An export file of computed data is done and saved.

Temps de cycle : between 1 and 3mn per part.

Autonomie : between 4 to 16hrs operating on a 3x8hr basis.

ASPECT CONTROL :

ASPECT CONTROL :

ASPECT CONTROL :

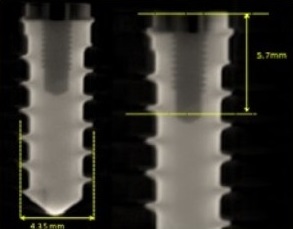

A product's appearance plays a more and more important role in a client's perception of its quality. Beyond its features, a product must have a flawless aspect. At a given level of magnification, a deviation from an ideal surface can always be detected. To detect this deviation, companies put in place surface aspect visual controls, which are usually done manually.

AUTOMATED UNITS :

AUTOMATED UNITS :

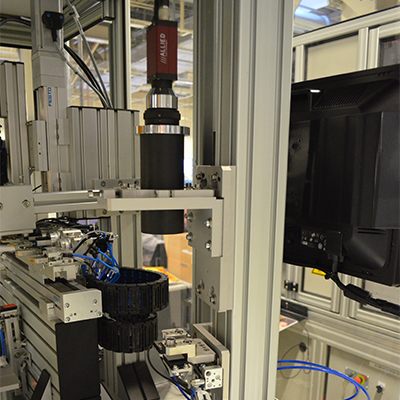

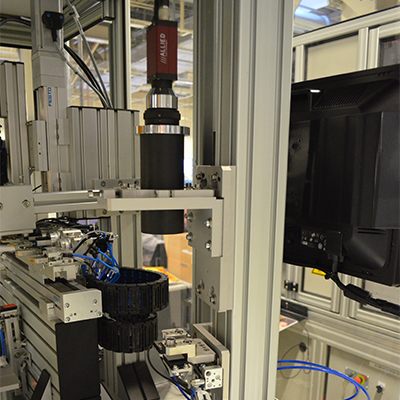

Using National Instruments software, ALPROBOTIC has developed aspect control units dedicated to small high added value parts (surgical implants, watchmaking parts, aeronautics...).

From bulk or tray dispensing, the robot seizes the part and places it under different control cameras. The NOK parts are set aside. The pace depends on the controls needed and the number of surfaces to control.

Cycle time : from 10s per part.

Autonomy : between 4 to 16hrs operating on a 3x8hr basis.

X-RAY CONTROL :

NON-DESTRUCTIVE CONTROL :

NON-DESTRUCTIVE CONTROL :

SPECTROSCAN develops software and physical solutions for non-destructive control and tri-dimensional analysis based on x-ray imaging.

• Defect characterization and search : porosities, cracks...

• Internal/external tri-dimensional metrology and measuring.

• Fibre orientation analysis.

• Volumes adaptive grid.

AUTOMATED UNITS :

AUTOMATED UNITS :

In association with SPECTROSCAN, ALPROBOTIC develops non-destructive mechanized units dedicated to small high added value parts (surgical implants, watchmaking parts, aeronautics...).

From bulk or tray dispensing, the robot moves the parts between the x-ray generator and the sensor. Via a link with the control software network, the robot is able to set aside the NOK parts.

Cycle time : from 10s per part.

Autonomy : between 4 to 16hrs operating on a 3x8hr basis.

AUTOMATED LASER MARKING :

LASER MARKING :

LASER MARKING :

Today, laser marking is the only contactless technology used in parts traceability (plastic, metallic...) Laser marking speeds can be very high (several m/s). They are based on the type of material to mark and of the power of the laser.

AUTOMATED UNITS :

In association with IINDUSTRIAL LASER SYSTEMS, ALPROBOTIC has developed laser marking units dedicated to small high added value parts (surgical implants, watchmaking parts, aeronautics...).

From a bulk or tray feeding, the robot seizes the part and places it directly under the laser within the exact focal length (accuracy +/-0.03) or on a suitable support. Via the Ethernet network, the robot transmits the instructions to the laser and launches the marking. Once the marking is complete, the robot is able (as an option) to check the presence of the marking. The NOK parts are set aside. The speed depends on the marking and control to be done.

Cycle time : from 10s per part.

Autonomy : between 4 to 16hrs operating on a 3x8hr basis.

Remonter en haut de la page

Remonter en haut de la page

ALPROBOTIC SARL | 88 rue de Chartreuse - 38420 LE VERSOUD | RCS Grenoble : 499247682 | SIRET : 49924768200028 | contact@alprobotic.fr

OUR PRODUCTS :

OUR PRODUCTS : AUTOMATED WORKSHOPS :

AUTOMATED WORKSHOPS : MOBILE ROBOTICS :

MOBILE ROBOTICS :

SUPPLY OF ROBOTIC UNITS BY MOBILE ROBOT :

SUPPLY OF ROBOTIC UNITS BY MOBILE ROBOT :

AUTOMATED CLEANING LINE :

AUTOMATED CLEANING LINE : ULTRASONIC CLEANING :

ULTRASONIC CLEANING :

DE-GREASING LINE INTEGRATION :

DE-GREASING LINE INTEGRATION :

AUTOMATED SANDBLASTING :

AUTOMATED SANDBLASTING : SANDBLASTING :

SANDBLASTING :

AUTOMATED UNITS :

AUTOMATED UNITS :

AUTOMATED ANODIZATION :

AUTOMATED ANODIZATION : ANODIZATION :

ANODIZATION :

DIMENSIONNAL CONTROL :

DIMENSIONNAL CONTROL : DIMENSIONAL CONTROL :

DIMENSIONAL CONTROL :

AUTOMATED UNITS :

AUTOMATED UNITS :

ASPECT CONTROL :

ASPECT CONTROL : ASPECT CONTROL :

ASPECT CONTROL :

AUTOMATED UNITS :

AUTOMATED UNITS :

X-RAY CONTROL :

X-RAY CONTROL : NON-DESTRUCTIVE CONTROL :

NON-DESTRUCTIVE CONTROL :

AUTOMATED UNITS :

AUTOMATED UNITS :

AUTOMATED LASER MARKING :

AUTOMATED LASER MARKING : LASER MARKING :

LASER MARKING :